The Role of Cellulose Ether ın Self-Levelıng Floor Applıcatıons

Self-leveling floor compounds have transformed modern construction by delivering smooth, flat surfaces ready for final finishes—without labor-intensive manual correction. At the heart of these formulations lies a critical component: cellulose ether. Known for enhancing flow, water retention, bonding, and stability, cellulose ether is indispensable to self-leveling technology. Let’s dive into why.

What Makes Self-Leveling Floors Work?

Self-leveling compounds are special cementitious or gypsum-based mortars that, by gravity and formulation, spread evenly across a substrate to create perfectly flat surfaces with minimal labor. Their fluidity allows for rapid and large-scale coverage in interior construction and renovation projects. But achieving consistent flow, curing, and adhesion without cracking or separation requires more than good mix proportions—it takes smart additives like cellulose ethers.

How Cellulose Ether Enhances Performance

1. Superior Fluidity & Flow Control

Self-leveling mortars must maintain ideal flow (often 10–12 cm spread) to self-flatten effectively. Cellulose ether—particularly HPMC—adds precise rheological control, ensuring smooth, even coverage without altering mix composition.

2. Effective Water Retention

Quick substrate absorption or rapid evaporation can cause uneven curing, weak bonding, or surface cracks. Cellulose ether retains moisture in the mix, allowing full cement hydration and optimal bond strength.

3. Stabilized Coagulation Time

Controlled setting is important. Cellulose ether tweaks early hydration rates—delaying skin formation and staying pliable just long enough for smooth leveling without slump.

4. Enhanced Bond Strength

By forming a polymer film around cement particles, cellulose ether enhances plasticity, flexibility, and interfacial adhesion—creating a durable bond between mortar and substrate.

5. Prevents Segregation

Without stabilizers, mixes can separate (water rising, solids sinking) resulting in compromised strength. Cellulose ether maintains homogeneity from first pour to final set.

Key Performance Drivers – A Technical Snapshot

| Property | Effect of Cellulose Ether Inclusion |

| Fluidity Control | Ensures self-leveling consistency without over-fluidity |

| Water Retention | Supports hydration, reduces cracking and shrinkage |

| Set Time Regulation | Enables precise working window without early skin buildup |

| Bond Strength | Enhances adhesion to substrates with long-term durability |

| Homogeneity | Prevents mix segregation, ensuring quality surfaces |

Broader Applications in Construction

Beyond self-leveling floors, cellulose ethers play key roles in enhancing dry-mix products like tile adhesives, renders, plasters, and joint fillers—improving adhesion, water control, and working properties across substrates.

In Summary

Self-leveling floor applications demand a blend of fluidity, stability, adhesion, and durability. Cellulose ether, especially HPMC grades, delivers all this by improving water retention, rheology, settling time, and bonding—ensuring flat, reliable surfaces with less labor and better results.

Ready to learn more or find the right cellulose ether for your self-leveling applications?

Our team at TS Group is here to help you choose the perfect solution for durability, workability, and long-term performance. Contact us today to discuss your project needs and discover how we can support your success.

Frequently Asked Questions (FAQ)

1. Which cellulose ether for self-leveling floors?

HPMC is most commonly used due to its viscosity, water retention, and compatibility with cementitious systems.

2. How much cellulose ether should be used?

Typically 0.2–0.5% of the dry mix weight—enough to optimize performance without over-thickening or delaying curing.

3. Does cellulose ether affect compressive strength or cure time?

Higher amounts can slightly delay setting and reduce early strength. It’s essential to balance performance and dosage appropriately.

4. Can cellulose ether replace multiple additives?

Yes—its multifunctionality (thickening, stabilizing, water retention) often replaces multiple components, simplifying formulation.

5. What factors should determine cellulose ether selection?

Consider viscosity grade, solubility, local climate, substrate characteristics, and application requirements to choose the optimal grade.

HEC vs. HPMC ın Paints: Why HEC ıs the Superıor Choıce

While Hydroxypropyl Methylcellulose (HPMC) and Hydroxyethyl Cellulose (HEC) are both cellulose ethers used in water-based paint formulations, HEC, particularly TS Group’s advanced HEC, is often more suitable for paints than HPMC. This report highlights the key reasons why HEC is the preferred choice for achieving high-quality paint formulations, directly addressing and overcoming common issues associated with other thickeners.

Key Advantages of HEC in Paint Formulations:

1. Superior Thickening Efficiency at Low Doses: HEC provides a highly effective thickening action even at low concentrations. This enables formulators to achieve desired viscosity levels efficiently, optimizing material usage and overall paint formulation costs.

2.Broad pH Stability: HEC exhibits excellent stability across a wide pH range (typically 2-12). This broad compatibility ensures consistent performance and viscosity maintenance in diverse paint systems, regardless of their acidity or alkalinity.

3.Consistent Viscosity Across Temperature Ranges (Non-Thermogelation): A significant advantage of HEC is its stable viscosity profile over a broad temperature range. Unlike other thickeners that may exhibit thermogelation (forming a gel upon heating and causing viscosity drop), HEC maintains consistent properties, which is crucial for stable paint performance during manufacturing, storage, and application, even under varying temperature conditions.

4. Excellent Sag Resistance for High-Build Coatings: HEC is highly effective at imparting outstanding sag resistance, which is critical for high-build coatings applied on vertical surfaces. It significantly increases viscosity at low shear rates, helping the paint stay in place and preventing dripping or running, thus ensuring a uniform and professional finish.

5. Improved Pigment Suspension and Dispersion: HEC aids in keeping pigments and fillers evenly distributed throughout the paint. This prevents settling during storage and ensures consistent color and opacity in the applied film, leading to a more uniform and vibrant final appearance.

6. Enhanced Water Retention: HEC provides excellent water retention properties, which extend the open time of the paint. This is particularly beneficial in hot or dry conditions, allowing for proper film formation, improved adhesion to various substrates, and preventing issues like cracking due to premature drying.

7. Outstanding Spatter Resistance and Improved Workability: HEC has been specifically developed to enhance the application properties of paints. It significantly contributes to outstanding spatter resistance, leading to a cleaner application process and less material waste. Furthermore, it improves the paint’s workability, making it easier to apply smoothly with various tools.

8. Good Can Stability: Paints formulated with HEC exhibit good can stability, meaning they maintain their desired viscosity and overall quality during extended storage periods in their containers, resisting sedimentation or separation.

9. Easy Dispersion and Dissolution in Cool Water (No Lumps): A key user-friendly feature of HEC is its easy dispersion and complete dissolution in cool water without forming lumps. This simplifies the manufacturing process, saves time, and ensures a homogeneous paint mixture.

10. Excellent Color Acceptance and Development: HEC contributes to excellent color acceptance and development in paint formulations. This means that colorants integrate effectively into the paint, resulting in true, vibrant, and consistent colors that meet specification.

11. Biostability: HEC is a biostable polymer, meaning it is less susceptible to microbial degradation during storage, which helps maintain the paint’s viscosity and performance over time.

Negative Effects of Using HPMC in Paints:

While HPMC has applications in various industries, its use in paint formulations can present several limitations compared to HEC:

–Thermogelation and Temperature Sensitivity: A primary drawback of HPMC is its thermogelation property. HPMC solutions decrease significantly in viscosity as temperature rises and can even form a gel at elevated temperatures. This leads to viscosity instability during high-temperature storage or transport, potentially causing pigment settling, reduced sag resistance, and inconsistent application behavior in warm climates.

–Challenging Dispersion and Dissolution: HPMC often requires more specific and rigorous mixing conditions for complete dispersion and dissolution in water, sometimes necessitating a combination of cold water dispersion followed by heating or very vigorous agitation to prevent lump formation. This can complicate the manufacturing process and increase production time compared to HEC’s easier dissolution.

–Limited Biostability: HPMC is generally less biostable than HEC, making paint formulations more susceptible to microbial attack during storage. This can lead to viscosity loss, unpleasant odors, and compromised paint quality over time, requiring higher levels of biocides.

–Potentially Lower Thickening Efficiency in Certain Systems: In specific paint formulations, especially those requiring high film build or particular rheological profiles, HPMC may offer a less efficient thickening effect compared to HEC, potentially necessitating higher dosages to achieve desired results.

HEC offers a comprehensive suite of benefits for water-based paint formulations, positioning it as a superior choice over HPMC for demanding applications. Its inherent advantages such as superior thickening efficiency, broad pH and temperature stability (crucially, without thermogelation), excellent sag resistance, and inherent biostability are significantly enhanced by its outstanding spatter resistance, improved workability, good can stability, easy dissolution, and excellent color acceptance. By contrast, HPMC’s tendencies towards thermogelation leading to viscosity instability, more demanding dissolution processes, and limited biostability make HEC the more reliable and high-performing option for manufacturers seeking consistency, ease of processing, and ultimately, superior paint quality.

Wood Pulp vs. Cotton Lınter for Cellulose Ethers ın Constructıon & Coatıngs

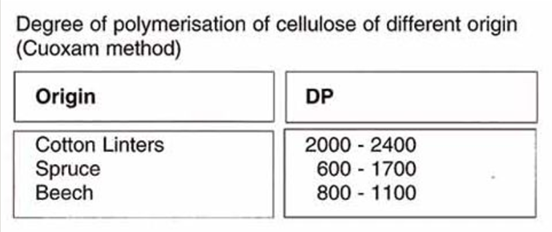

The performance of cellulose ethers is largely determined by their primary raw material: cellulose. While both wood pulp and cotton linter serve as significant sources, their inherent differences lead to distinct characteristics in the final cellulose ether products, directly impacting their suitability for various applications in these industries.

Wood Pulp-Based Cellulose

Wood pulp has historically been the most prevalent cellulose source for ethers used in construction and coatings due to its widespread availability and relative cost-effectiveness. However, recent global events, including geopolitical conflicts and supply chain disruptions, have significantly impacted the timber and pulp markets. This has led to increased wood pulp prices and greater market volatility, challenging its traditional economic advantage.

Key Characteristics in Construction & Coatings:

For Wood Pulp:

–Purity & Performance: Cellulose ethers derived from wood pulp typically have a lower cellulose content (85-95%) and residual impurities. For construction applications like tile adhesives, renders, plasters, and self-leveling compounds, these ethers provide essential thickening, water retention, and workability. In coatings, they offer good general rheology modification. While highly effective for these purposes, minor impurities can sometimes influence the final product’s clarity or long-term stability in highly sensitive coating formulations.

–Fiber Properties: Wood fibers are shorter and less uniform, which can result in broader molecular weight distribution in the final ether. This generally provides a robust and versatile performance profile suitable for the bulk of construction and standard coating applications, where extreme precision in rheology is less critical than cost and fundamental performance.

For Cotton Linter:

Cotton linter, the short fibers from cottonseed, is a highly purified form of cellulose. It is considered a premium raw material, particularly for cellulose ethers destined for applications demanding superior performance and purity.

Key Characteristics in Construction & Coatings:

–Purity & Performance: Cotton linter boasts a much higher cellulose content (>98%) with significantly fewer impurities. This translates to cellulose ethers with superior clarity, consistency, and chemical stability.

–Fiber Properties: Linter fibers are generally longer and more uniform, leading to a more consistent etherification reaction and cellulose ethers with a narrower molecular weight distribution. This allows for more precise control over viscosity, rheology, and film-forming properties, which is highly valued in demanding coating applications.

–Environmental advantage: Unlike wood pulp, which requires harvesting trees, cotton linters do not contribute to deforestation. This helps preserve forest ecosystems, biodiversity, and carbon sequestration capabilities. Besides this, cotton is an annually renewable crop, making cotton linter a consistently renewable source of cellulose.

For the construction and coatings industries, the choice between wood pulp and cotton linter as raw materials for cellulose ethers involves a strategic decision balancing cost, required performance, and specific application demands. While wood pulp-based ethers remain indispensable for their foundational properties and widespread use, the increasing cost pressures on wood pulp are prompting a closer look at cotton linter, especially because it offers significant environmental advantages.

Consıderatıons for Cellulose Ether Formulatıon for Natural vs. FGD (Chemıcal) Gypsum Applıcatıons

Gypsum plasters and boards rely on modified cellulose ethers for water retention, workability, and rheology. However, natural gypsum and chemical gypsum (FGD) differ in purity, particle size, and ionic content, factors that affect how CEs perform. Optimizing CE production for each type improves consistency and application quality.

1. Key Differences in Gypsum Types

Natural Gypsum: Lower purity, broader particle size, fewer soluble salts, slower reactivity.

FGD Gypsum: Higher purity, finer particles, higher ionic strength, faster dissolution.

These characteristics influence CE hydration, viscosity stability, and set-time behavior.

Industrial gypsum is usually a blend of CaSO₄, CaSO₄·½H₂O, and CaSO₄·2H₂O, with proportions varying depending on the country and region. Because of this variability, it is important to carry out tests under actual conditions to identify the most suitable cellulose ether type and dosage. In most gypsum-based mortars, adding around 0.2% HPMC or similar cellulose ether can greatly enhance workability, reduce cracking, and produce smooth, uniform wall finishes.

2. Production Considerations

Salt Tolerance

FGD: Requires CEs with higher electrolyte resistance to maintain viscosity in high-salt pore solutions.

Natural: Standard grades suffice.

· Retardation Control

FGD: Minimize set retardation to prevent delays.

Natural: Moderate retardation is acceptable to extend open time.

· Viscosity Grade

FGD: Slightly higher viscosity to offset finer particle size and higher water demand.

Natural: Mid-range viscosity is usually adequate.

· Hydrophobe Modification

Improves sag resistance and yield stress; use more in FGD formulations.

· Air Entrainment

FGD: Opt for very low-air grades to counter salt-induced bubble instability.

Natural: Low-air grades are generally sufficient.

· Solubility Profile Controlled delayed solubility is valuable for FGD mixes to prevent lumping.

3. Why Tailoring CE Matters

Cellulose ether does not perform the same in every gypsum product, so it needs to be matched to the type of gypsum being used. Natural gypsum and FGD gypsum have different purity levels, particle sizes, and salt content. These differences affect how the plaster holds water, how quickly it sets, and how easy it is to apply. If the wrong type of cellulose ether is used, it can cause slow setting, poor flow through machines, sagging, or uneven surfaces. Adjusting properties like salt resistance, viscosity, setting influence, dissolving speed, and air content to suit the specific gypsum type ensures the plaster works well every time. This keeps the quality consistent, makes the work easier for applicators, and avoids wasted time and money when the gypsum source changes.

| Parameter | Natural Gypsum | FGD Gypsum |

| Salt Tolerance | Standard salt resistance is usually enough | High salt resistance needed for stable viscosity |

| Viscosity Grade | Medium viscosity for good workability | Slightly higher viscosity to handle finer particles |

| Set Retardation | Moderate retardation can be beneficial | Low retardation to avoid delays |

| Hydrophobe Modification | Light or none, for smooth trowel feel | Light to moderate, to improve sag resistance |

| Air Entrainment | Low air content is generally fine | Very low air to control bubble stability in high-salt systems |

| Solubility Profile | Standard solubility is suitable | Delayed solubility helps prevent lumping in high-salt water |

| Typical Dosage | Around 0.2% of binder weight | Around 0.2%–0.3% of binder weight |