Wood Pulp vs. Cotton Lınter for Cellulose Ethers ın Constructıon & Coatıngs

The performance of cellulose ethers is largely determined by their primary raw material: cellulose. While both wood pulp and cotton linter serve as significant sources, their inherent differences lead to distinct characteristics in the final cellulose ether products, directly impacting their suitability for various applications in these industries.

Wood Pulp-Based Cellulose

Wood pulp has historically been the most prevalent cellulose source for ethers used in construction and coatings due to its widespread availability and relative cost-effectiveness. However, recent global events, including geopolitical conflicts and supply chain disruptions, have significantly impacted the timber and pulp markets. This has led to increased wood pulp prices and greater market volatility, challenging its traditional economic advantage.

Key Characteristics in Construction & Coatings:

For Wood Pulp:

- Purity & Performance: Cellulose ethers derived from wood pulp typically have a lower cellulose content (85-95%) and residual impurities. For construction applications like tile adhesives, renders, plasters, and self-leveling compounds, these ethers provide essential thickening, water retention, and workability. In coatings, they offer good general rheology modification. While highly effective for these purposes, minor impurities can sometimes influence the final product’s clarity or long-term stability in highly sensitive coating formulations.

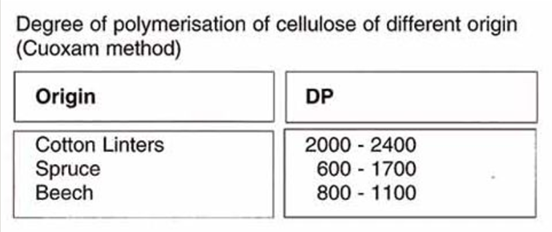

- Fiber Properties: Wood fibers are shorter and less uniform, which can result in broader molecular weight distribution in the final ether. This generally provides a robust and versatile performance profile suitable for the bulk of construction and standard coating applications, where extreme precision in rheology is less critical than cost and fundamental performance.

For Cotton Linter:

Cotton linter, the short fibers from cottonseed, is a highly purified form of cellulose. It is considered a premium raw material, particularly for cellulose ethers destined for applications demanding superior performance and purity.

Key Characteristics in Construction & Coatings:

- Purity & Performance: Cotton linter boasts a much higher cellulose content (>98%) with significantly fewer impurities. This translates to cellulose ethers with superior clarity, consistency, and chemical stability.

- Fiber Properties: Linter fibers are generally longer and more uniform, leading to a more consistent etherification reaction and cellulose ethers with a narrower molecular weight distribution. This allows for more precise control over viscosity, rheology, and film-forming properties, which is highly valued in demanding coating applications.

- Environmental advantage: Unlike wood pulp, which requires harvesting trees, cotton linters do not contribute to deforestation. This helps preserve forest ecosystems, biodiversity, and carbon sequestration capabilities. Besides this, cotton is an annually renewable crop, making cotton linter a consistently renewable source of cellulose.

Conclusion

For the construction and coatings industries, the choice between wood pulp and cotton linter as raw materials for cellulose ethers involves a strategic decision balancing cost, required performance, and specific application demands. While wood pulp-based ethers remain indispensable for their foundational properties and widespread use, the increasing cost pressures on wood pulp are prompting a closer look at cotton linter, especially because it offers significant environmental advantages.

Which types of cellulose ethers are used in tile adhesives?

HPMC and HEMC are commonly used to improve workability, water retention, and bond strength, while HEC is occasionally used for specific cementitious applications.

How do cellulose ethers improve the performance of tile adhesives?

They enhance spreadability, extend open time for large tiles, control water retention for consistent curing, and reduce shrinkage during drying.